Product Introduction

This is a highly cost-effective nut color sorter with an excellent sorting system that uses AI technology to capture and process images, backup settings, mode backup and transmission, and a user-friendly operating system. Convenient, fast, ultra high definition full color imaging and recognition system. The sorting accuracy is as high as 99.99%, and it has excellent performance in color and shape selection, helping various food enterprises and nut processing enterprises to create high-quality nuts, stable and high yield, and improve efficiency. Comprehensively ensuring quality and safety.

Application Field

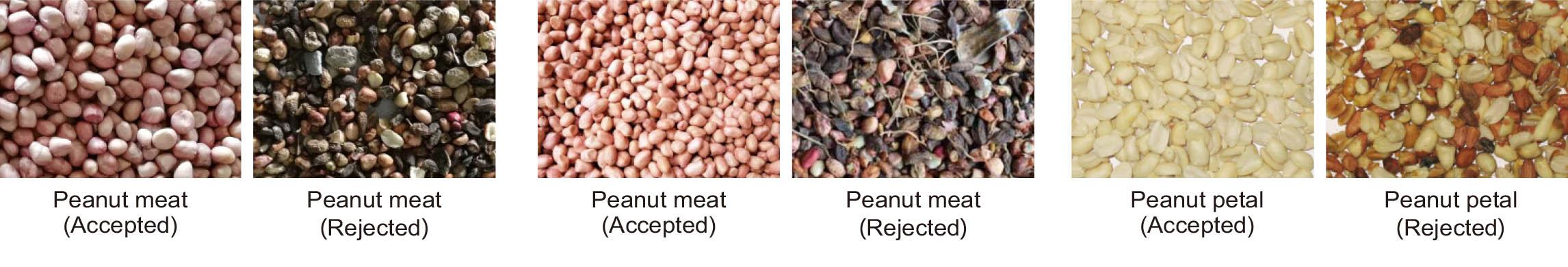

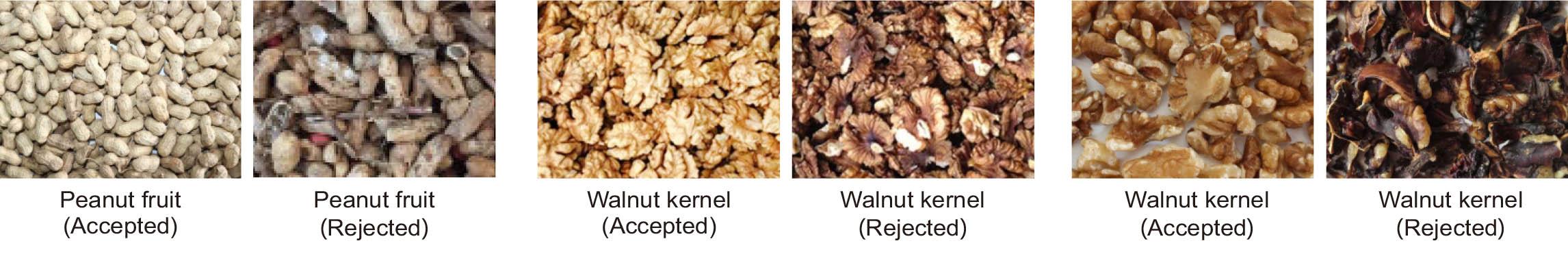

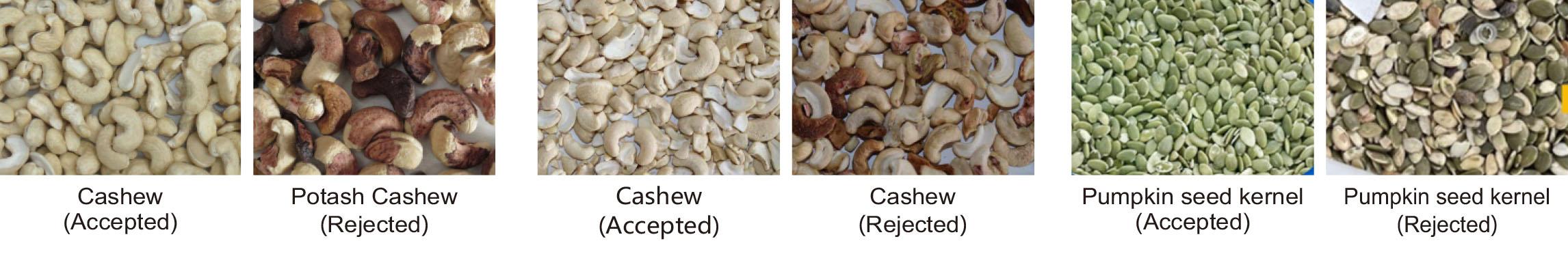

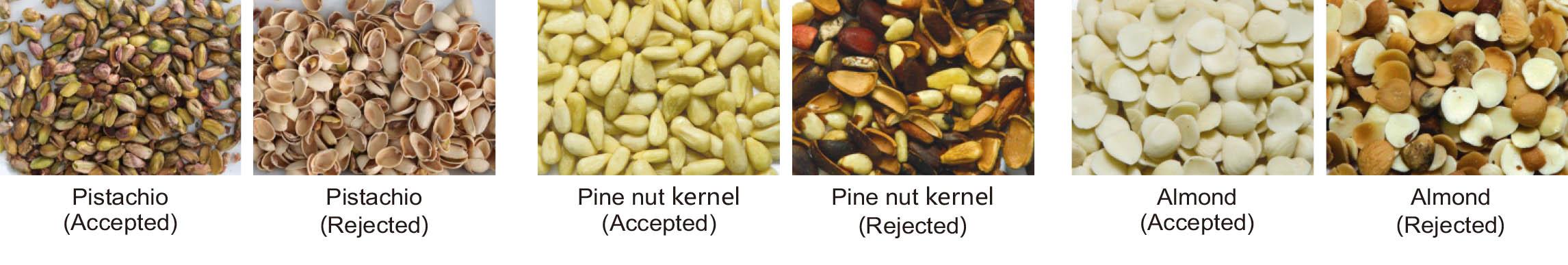

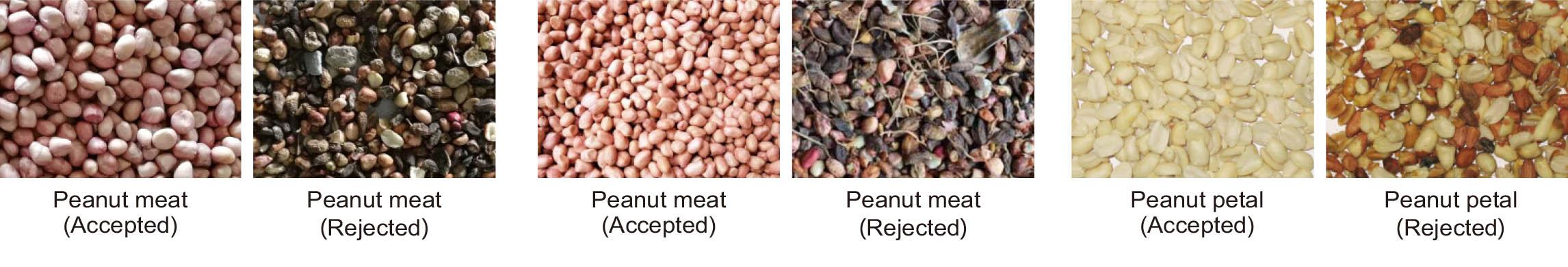

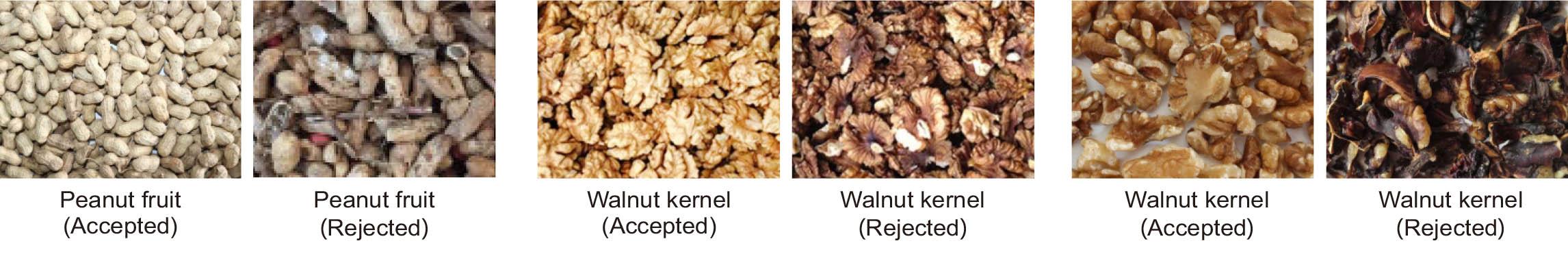

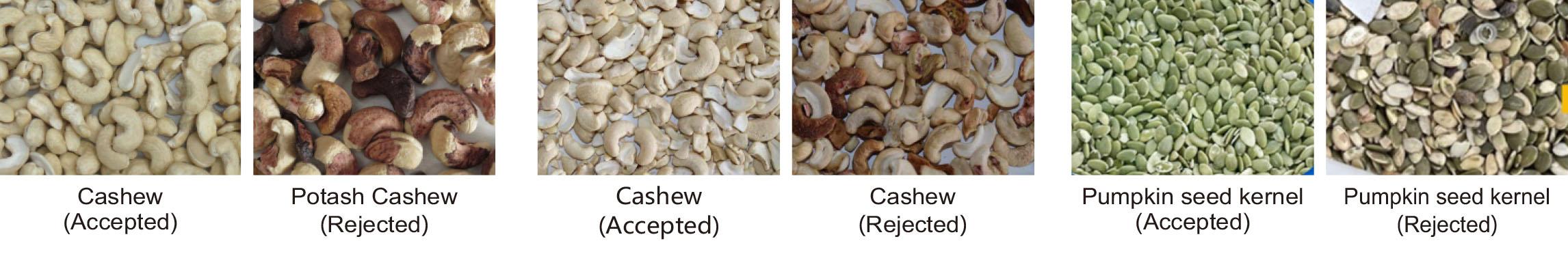

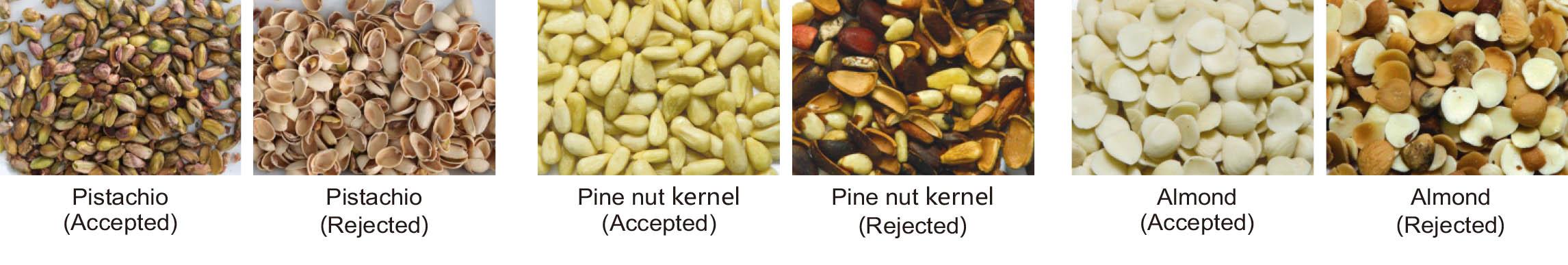

Suitable for the classification and grading of various nut materials such as nuts, walnuts, peanuts, almonds, cashews, pine nuts, hazelnuts, macadamia nuts, melon seeds, magnolias, figs, pistachios, ginkgo biloba, olives, raisins, chestnuts, candied fruits, etc

Product Specificities

-

Artificial intelligence technology

The artificial intelligence technology of color selection machine can manage and analyze the large amount of data generated during the color selection process. It can collect, store, and process various color selection data, providing statistics and analysis of color distribution, color difference, and other data. This data management and analysis function helps users understand and optimize the production process, and improve product quality.

-

Intelligent operation interface

The intelligent operation interface of color sorter usually has intelligent optimization and setting functions. It can automatically adjust and optimize parameters based on the operation status and feedback information of the device to achieve better color selection results. In addition, it can also provide one click settings, quickly switching and adapting to different color requirements through preset parameter combinations.

-

Ultra high speed FPGA processor

The ultra high speed FPGA processor can respond to input signals in real time and perform fast data processing and analysis. During the color selection process, it can monitor and recognize color information in the image in real-time, and respond promptly. This enables the color sorter to perform real-time color selection operations on high-speed production lines.

-

Intelligent remote control system

The remote control system allows operators to customize settings and intelligently optimize according to their own needs. Operators can adjust the parameters and algorithms of the color sorter according to different product types and production requirements to achieve the best sorting effect and production efficiency. The system can also gradually optimize performance and automatically adjust settings through learning and adaptive techniques, improving the accuracy and efficiency of color selection.

-

Intelligent visual image acquisition system

The intelligent visual image acquisition system can monitor and provide real-time feedback on the data and results during the color selection process. Operators can view image data in real-time through a visual interface and obtain feedback on color selection results. This can adjust color selection parameters and strategies in a timely manner, improving the accuracy and stability of color selection.

-

Intelligent adjustable light source technology

Intelligent adjustable light source technology adopts efficient and energy-saving light sources and control systems, which can adjust the light source according to actual needs and reduce energy consumption. This helps to reduce energy costs while also complying with environmental protection requirements.

-

High quality and durable solenoid valve

Due to the possible presence of special chemicals or corrosive gases in the working environment of color sorting machines, quality solenoid valves are usually made of corrosion-resistant materials, which can effectively resist corrosion and ensure long-term reliable operation.

-

Balanced and stable feeding system

The balanced feeding system can automatically adjust the speed and pressure of the feed stream according to actual needs to reduce energy consumption. By reducing unnecessary material flow and the use of compressed air, it can effectively save energy costs.

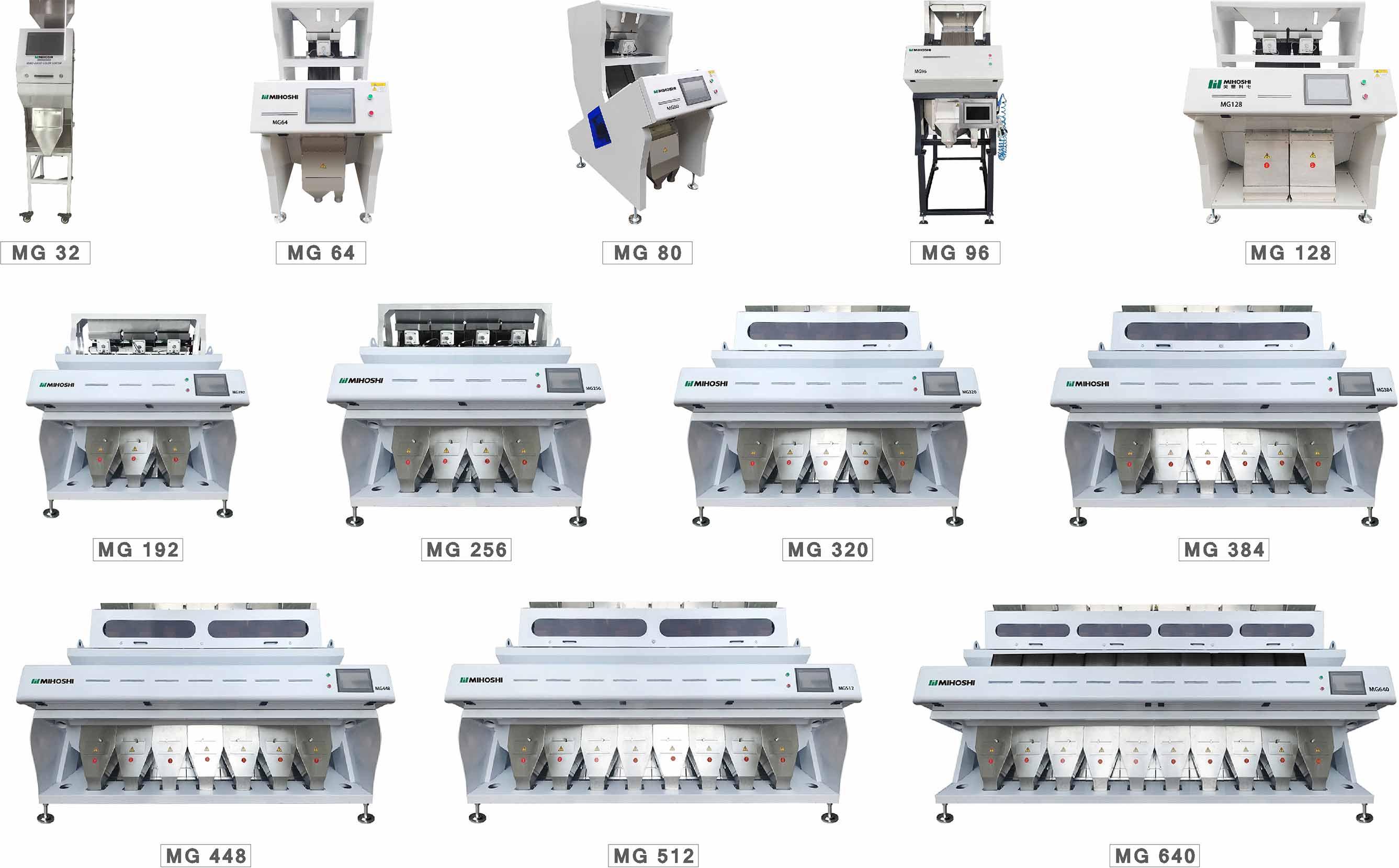

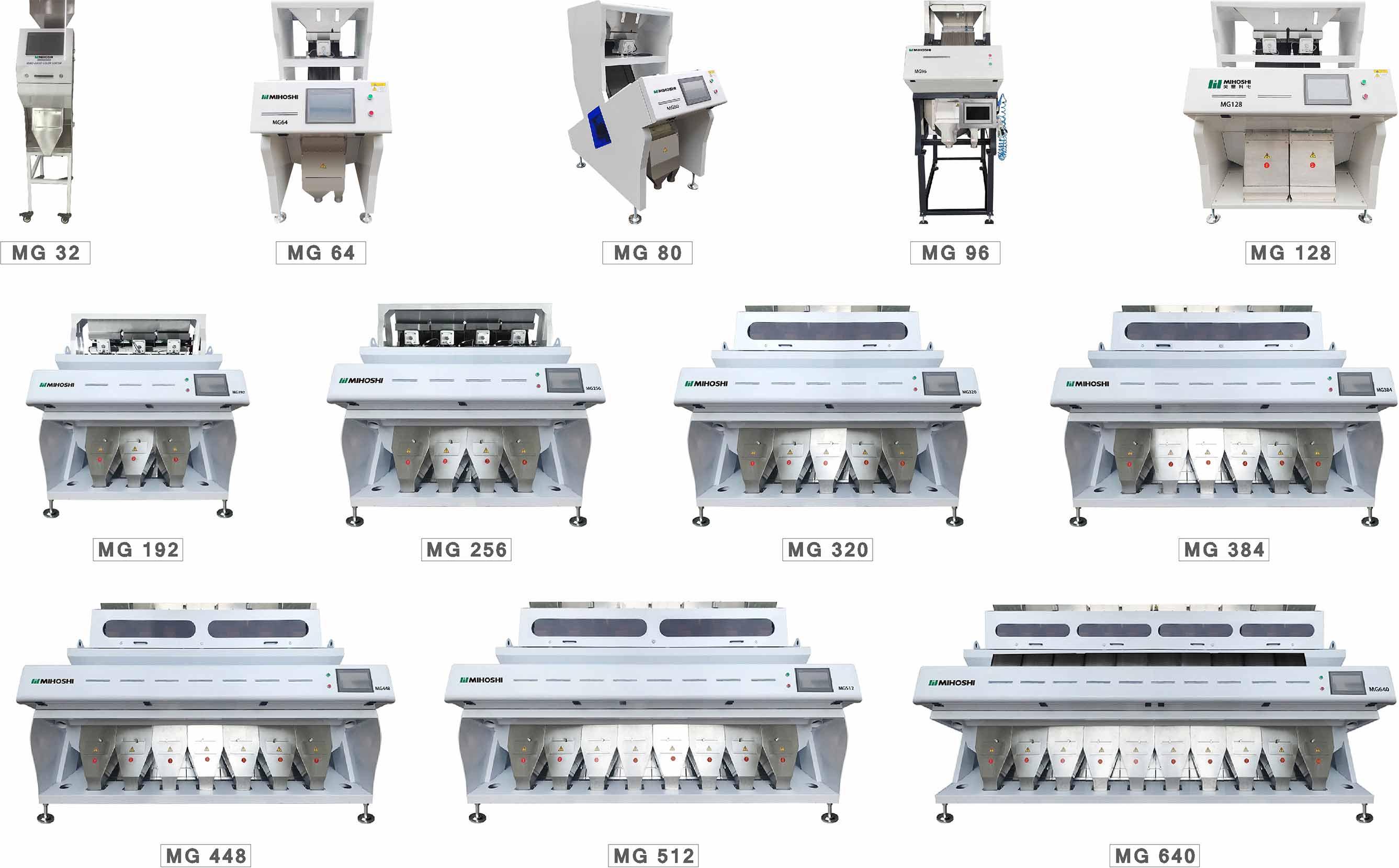

Color sorter product display (channel type)

Product Specificities

Technicial Specifications

| Product model |

Capacity

(T/h)

|

Accuracy

(%)

|

Voltage

(V/Hz)

|

Power

(kW)

|

Air pressure

(Map)

|

Air consumption

(L/min)

|

Weigh

t(Kg)

|

Dimension

(mm)

|

| MG32 |

0.2-0.5 |

>99.99% |

220/50 |

0.5-0.8 |

0.6-0.8 |

0.1-0.3 |

120/180 |

590X1504X1760 |

| MG64 |

0.8-1.6 |

>99.99% |

220/50 |

0.8-1.5 |

0.6-0.8 |

0.3-0.8 |

300/350 |

880X1504X1760 |

| MG80 |

1-2 |

>99.99% |

220/50 |

1-1.8 |

0.6-0.8 |

0.3-0.8 |

350/400 |

900X1504X1760 |

| MG96 |

1-3.5 |

>99.99% |

220/50 |

1.2-1.8 |

0.6-0.8 |

0.4-0.9 |

300/400 |

1550X940X1750 |

| MG128 |

2-6 |

>99.99% |

220/50 |

1.3-2.2 |

0.6-0.8 |

0.5-1.0 |

700/860 |

1314X1504X1760 |

| MG192 |

3-9 |

>99.99% |

220/50 |

1.5-2.5 |

0.6-0.8 |

0.8-1.5 |

950/1000 |

1650x1504X1760 |

| MG256 |

4-12 |

>99.99% |

220/50 |

1.8-3 |

0.6-0.8 |

1.0-2.0 |

1100/1200 |

1986X1504X1760 |

| MG320 |

5-15 |

>99.99% |

220/50 |

2.2-3.7 |

0.6-0.8 |

1.3-2.1 |

1280/1350 |

2322x1504X1760 |

| MG384 |

6-18 |

>99.99% |

220/50 |

3.6-4.5 |

0.6-0.8 |

2.0-3.5 |

1400/1500 |

2658X1504X1760 |

| MG448 |

7-21 |

>99.99% |

220/50 |

4.1-5.5 |

0.6-0.8 |

2.5-4.3 |

1500/1600 |

2994x1504X1760 |

| MG512 |

8-24 |

>99.99% |

220/50 |

4.7-6 |

0.6-0.8 |

3.0-4.5 |

1700/1800 |

3330X1504X1760 |

| MG640 |

10-30 |

>99.99% |

220/50 |

4.5-7.5 |

0.6-0.8 |

5.0-6.5 |

2000/2250 |

3666X1504X1760 |

| MG768 |

12-38 |

>99.99% |

220/50 |

5.2-8.8 |

0.6-0.8 |

7.0-8.5 |

2500/2600 |

4200x1504X1760 |

Installations Case

Our strengths